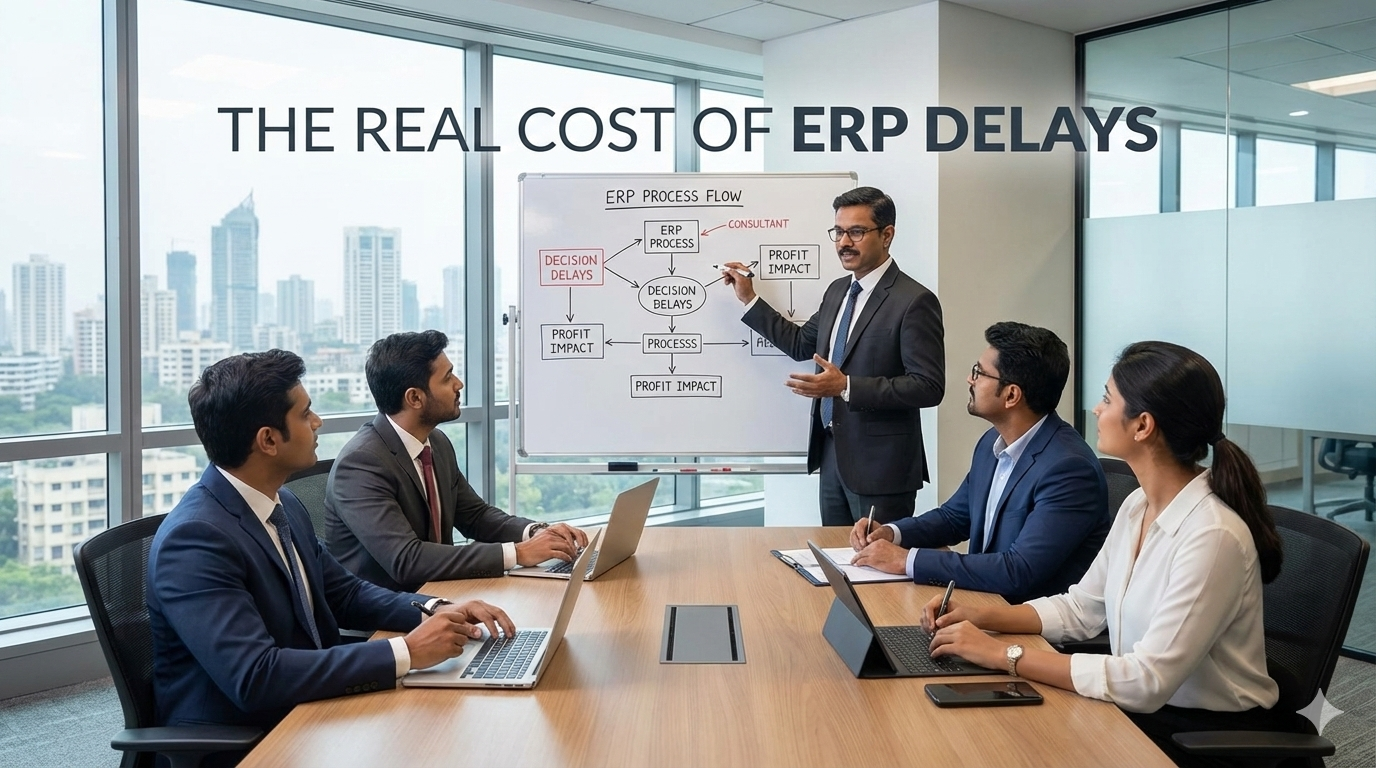

An ERP delay rarely appears as a single line item in your budget. When an ERP project slips, most business leaders first notice surface-level issues like missed milestones or extended timelines. Meanwhile, the real impact spreads quietly across departments, decisions, and months. By the time leadership steps in, the damage already sits buried in missed opportunities, frustrated teams, and eroded trust..

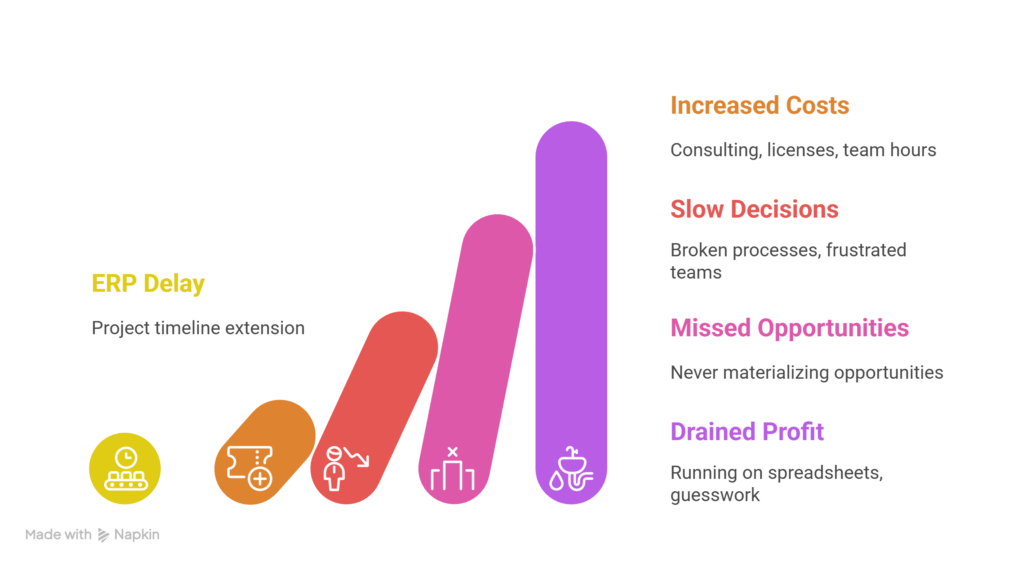

Every delayed ERP project costs more than money. When Consulting bills stretch, License costs extend, Core team members spend endless hours in review calls, UAT cycles and rework sessions, That feels expensive on paper. Here’s the thing: those visible costs matter far less than what the business loses quietly while the project remains stuck.

The real cost of a delayed ERP project never appears on the vendor invoice. It shows up in slow decisions, broken processes, frustrated teams, and opportunities that never materialize.

Across India, business owners sign ERP contracts to gain visibility, discipline and scalability. However, when projects slip by months, companies keep running on spreadsheets, phone calls and guesswork. That gap quietly drains profit while management assumes the ERP will fix everything soon. Unfortunately, “soon” never comes without process clarity.

At Jhavion Consultancy, we see this pattern across Indian manufacturing firms, trading companies, service organizations, healthcare providers, and high-growth startups.

Different Industries, Same story: The project didn’t fail, It just kept getting delayed.

Delay Means the Business Keeps Running on Broken Systems

An ERP project may pause, Business never does.

While implementation slows or stalls:

- Orders continue to flow as teams process sales and fulfill demand across multiple systems.

- Inventory moves between warehouses, stores, and job sites, tracked in disconnected tools with limited visibility.

- Finance teams send payments to vendors, partners, and employees through fragmented workflows that slow reconciliation and increase risk.

- Managers make daily decisions using incomplete data pulled from spreadsheets, reports, and emails.

All of this activity still takes place inside the same fragmented operating environment that originally drove the need for an ERP system, making it harder to scale, control costs, and maintain real-time insight into the business.

The impact shows up quickly:

- Sales commits delivery dates without access to real capacity data, which sets unrealistic expectations from the start.

- Operations stays in constant firefighting mode because planning never stabilizes or aligns with actual demand.

- Finance closes the books using Excel adjustments instead of relying on trusted system numbers, increasing risk and rework.

As a result, every ERP delay allows these problems to grow deeper and harder to unwind. Over time, the damage compounds:

- Confusion spreads across teams.

- Workarounds multiply in every department.

- Decisions rely more on guesswork than on facts.

Case Study:

A Manufacturing Story Every Indian CFO Recognizes

A mid-sized auto-component manufacturer in Pune invested in SAP to gain control over inventory, production planning, and finance. The implementation team scheduled go-live in nine months. However, after twelve months, nothing worked.

While the project stalled:

- Production kept running on Excel

- Stores continued adjusting stock manually

- Finance closed every month with adjustments.

- Sales promised delivery dates based on assumptions instead of capacity.

Each delay forced people to create workarounds. Over time, these workarounds became the real system. By the time SAP went live, employees trusted their spreadsheets more than the ERP.

That single delay destroyed adoption.

Why ERP Delays Hurt Service Businesses Even More

An IT services firm implemented Oracle ERP to manage projects, billing, and utilization. The project slipped by six months because teams never aligned on how to track project costs.

While the ERP stalled:

- Managers relied on local trackers to monitor project performance.

- Accounts teams raised invoices manually to keep cash moving.

These parallel processes created gaps between delivery, billing, and revenue recognition. Revenue leakage increased quietly, sprint by sprint.

ERP delays always train teams to avoid the ERP.

Retailers and Distributors Bleed Cash During ERP Delays

In Indian retail and distribution, ERP delays damage inventory accuracy more than anything else. A distributor started an ERP project to gain control over stock across multiple warehouses. The implementation dragged on for eight months without reaching stability. During that time, teams continued to move inventory using WhatsApp messages and Excel sheets instead of a centralized system.

As daily operations carried on outside the ERP, stock mismatches increased across locations. Dead and slow-moving inventory quietly piled up because no one had a reliable, real-time view of availability.

Finance teams lost visibility into true margins as purchase costs, transfers, and sales failed to reconcile cleanly. By the time the ERP came close to going live, the data it depended on no longer reflected reality.

The ERP arrived late, but the damage already happened.

So what looks like a simple project delay is actually a direct delay in business performance, cash flow, and leadership visibility.

That is the real cost no ERP vendor ever shows you.

Trust Breaks Long Before Go-Live

ERP delays quietly damage leadership credibility.

Early excitement fades as milestones slip and promised timelines lose meaning. Confidence drops when consultants rotate and context disappears. Engagement fades when delivery dates keep changing without clear accountability.

Teams stop planning around the ERP because it no longer feels real. Managers stop believing project updates because the numbers keep shifting. Executives stop trusting implementation data because it never matches what they see on the ground.

Once trust erodes, even a technically sound ERP struggles to gain adoption.

The system works until belief stops.

Why ERP Projects Actually Get Delayed

Contrary to popular belief, ERP delays rarely happen because the software is complex. They happen because business processes remain unclear.

During implementation, basic questions surface again and again:

- How does an order actually flow from sales to delivery?

- Who approves pricing, credit, and procurement?

- Which version of data is final and trusted?

- Who owns inventory at each stage?

- How does finance truly close the books?

Each department answers differently, based on how it works today rather than how the business should work tomorrow.

The ERP team then tries to configure the system on top of these contradictions. That’s where problems start:

- Rework follows almost immediately.

- Conflicts rise between teams.

- Timelines stretch as decisions get revisited again and again.

- Momentum fades.

The ERP rarely slow down because of technology.

They slows down not because the system cannot handle the business, but because the business never aligned on how it truly wants to operate. Without a clear process audit, ERP partners end up building systems on top of confusion. Every assumption leads to changes later. Every change adds delay.

Eventually, timelines collapse not because the software failed, but because the business never agreed on how it actually works.

How to Stop the Bleeding Before It Gets Worse ?

The True Cost of Delay

Every delayed ERP project:

- Increases manual work

- Weakens financial controls

- Creates shadow systems

- Destroys trust

- Reduces ROI

ERP does not fail suddenly. It bleeds slowly during delay.

Delays aren’t solved in meetings, and progress isn’t found in customization

What actually works is a Process Audit.

A structured process audit focuses on how work truly happens across the business, not how it looks on paper. It brings clarity before configuration and alignment before automation. A proper process audit helps you:

- Map how orders, inventory, billing, and closures actually flow

- Define clear ownership across sales, operations, finance, and inventory

- Eliminate data conflicts between departments

- Expose approval gaps and decision bottlenecks

- Align leadership on a single operating model

Once leadership agrees on how the business should run, ERP configuration becomes faster, cleaner, and far more predictable.

When rework ends, timelines stabilize and adoption follows.

Final Thought for Indian Business Leaders

If your ERP project feels stuck, the issue isn’t the software or the vendor. It’s the lack of process clarity.

When teams don’t clearly define how work should flow, ERP implementations stall, costs rise, and expected ROI disappears. Fix the processes first, and the ERP starts delivering real value.

Here’s the thing: most ERP failures don’t come from bad technology. They come from unclear ownership, undocumented workflows, and misaligned business rules. That’s where value leaks out.

JhaVion Consultancy helps you identify exactly where your ERP is losing value. We analyze your current processes, pinpoint gaps between business needs and system design, and create a clear roadmap before configuration or rework begins.

What this really means is faster ERP adoption, lower implementation risk, and measurable business outcomes. If you want your ERP system to work the way it was supposed to, start with process clarity. That’s how ERP success actually begins.

👉 Book your ERP Process Audit and stop paying the hidden cost of delay.